CNC Machining

CNC can be a powerful option for production

Oct 28, 2022

CNC manufacturing is an important pillar in today’s industrial hardware production, manufacturing thousands of parts and products daily for all types of industries.

Chances are that, wherever you are reading this article, there are CNC-manufactured objects around you. They can be electronics components, jewelry, bike or automotive parts, and even architectural features.

But what is CNC? What is CNC machining? How can you use CNC? Why is it important to understand these concepts?

In recent years CNC machining has become more accessible for SMEs and entrepreneurs thanks to online manufacturing platforms. For this reason, it is the best moment to learn about it and its manufacturing possibilities for you and your team. Keep reading to find out what CNC means and much more.

CNC for manufacturing

CNC is one of the most used manufacturing technologies by big and small companies around the world. It has continuously evolved since the first NC (numerical control) machines in the 1940s. During those years, the first modern CNC machine was invented by John T. Parsons only to be perfected in the 1950s with MIT's collaboration. Many industries rely on this technology to create everyday objects or surprising products year after year.

CNC machines have improved greatly over the past 35 years since CAD and CAM software became standardized in the late 1980s. However, still today not many people know what CNC means and when it’s the best time to use it.

What is CNC?

CNC stands for "Computer Numerical Control." It refers to the use of computer software to control and automate machine tools. CNC machines are capable of performing a wide variety of complex operations with high precision and accuracy.

The use of CNC technology has revolutionized manufacturing and made it possible to produce parts and products with greater efficiency and precision than ever before.

What is a CNC machine?

A CNC machine is a machine tool that uses computer software to control and automate its movements. This allows the machine to perform complex operations with high precision and accuracy. CNC machines are used in a wide variety of manufacturing industries, including automotive, aerospace, and medical device manufacturing.

The machines process specific CAD files to cut or shape parts and prototypes by using different tools, such as grinders, lathes, and turning mills. This process is called CNC machining.

What is CNC machining?

Machining processes fall into one of three groups of subtractive manufacturing: milling, turning, and drilling. The manufacturing process applied by a CNC machine using any of these machining tools is known as CNC machining.

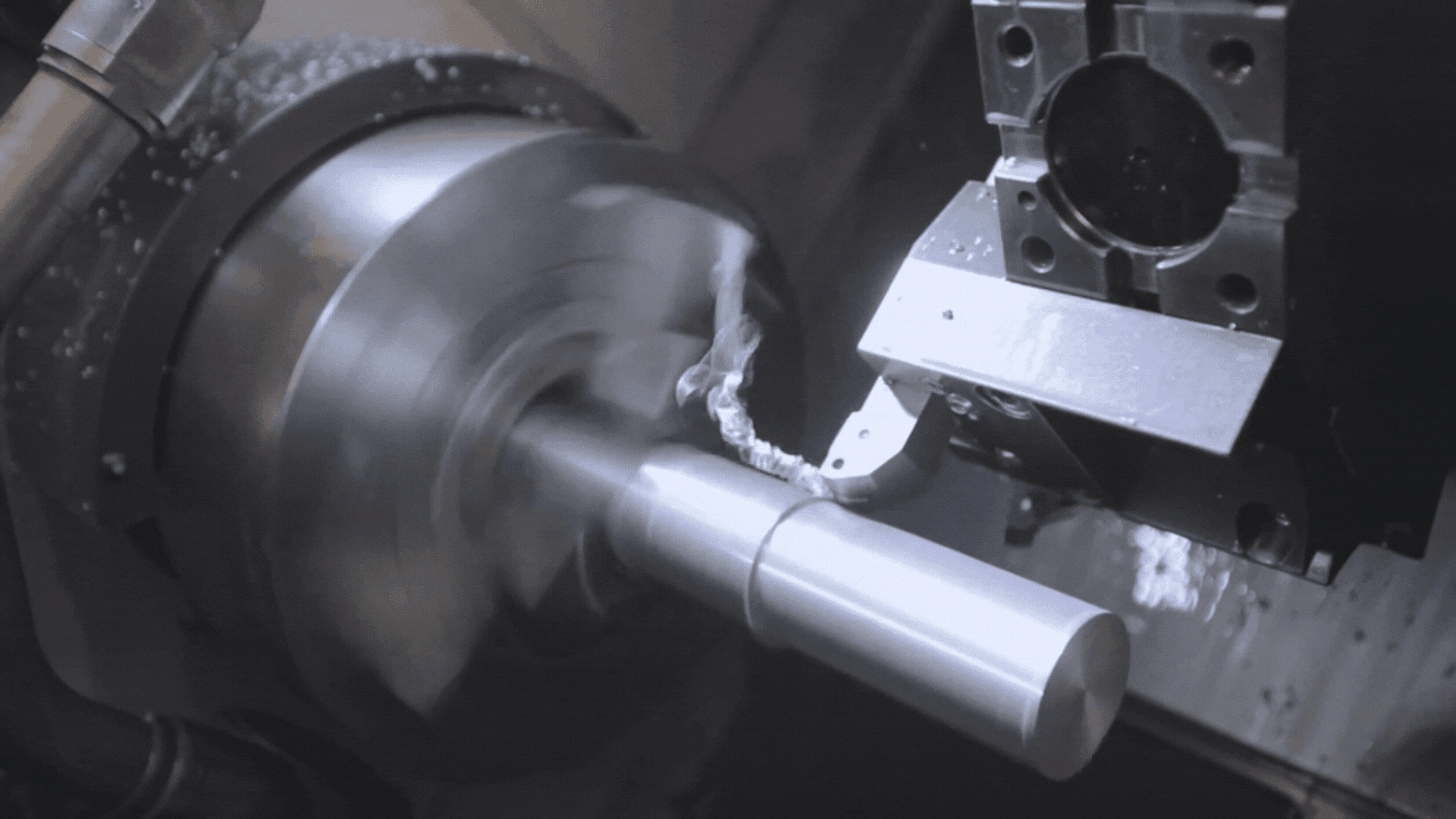

CNC turning process

CNC Turning operations rotate the workpiece at high speed, removing material from it by placing a cutting tool against the piece.

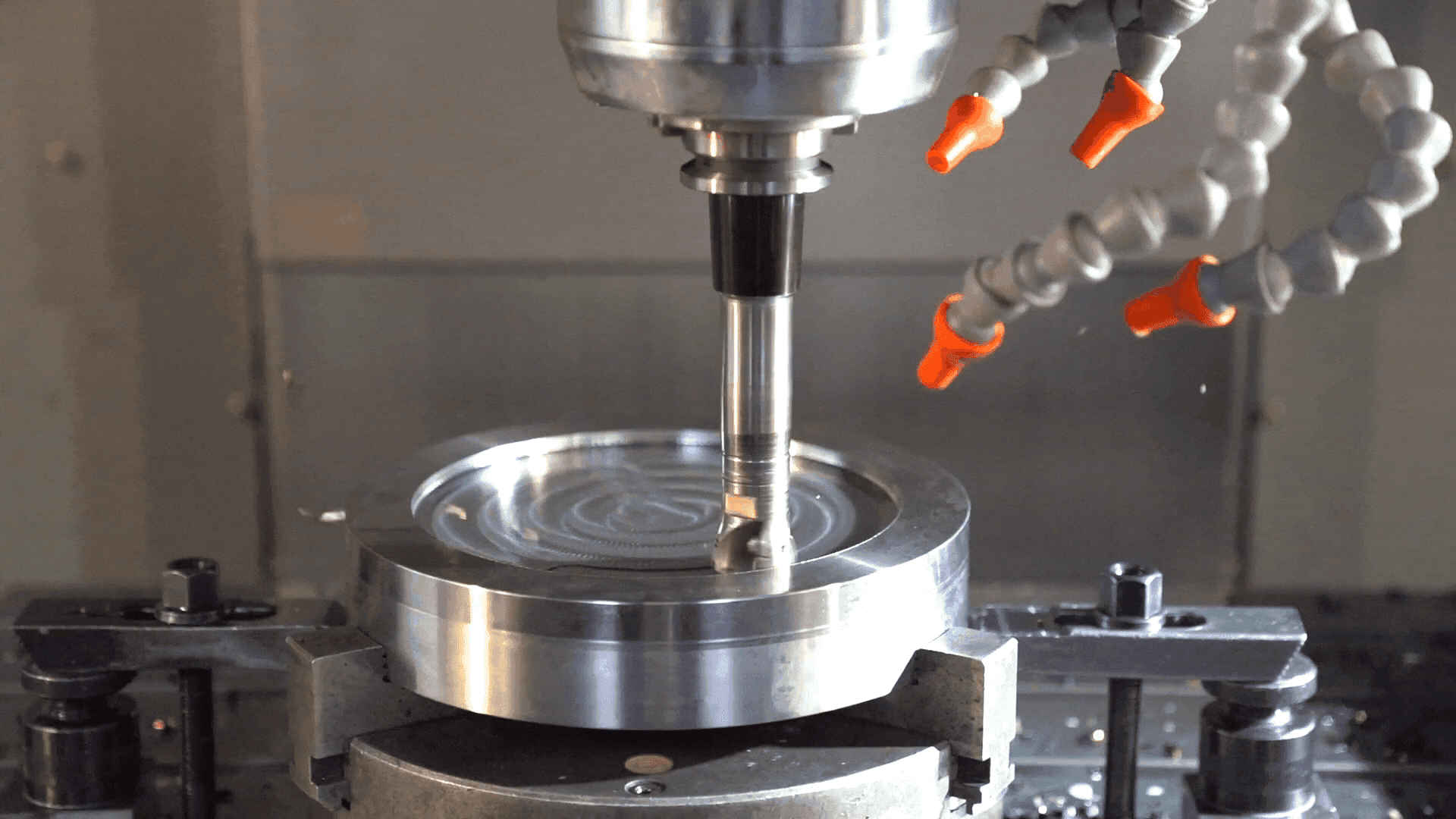

CNC milling process

CNC Milling is a subtractive process using a rotating cutting tool to remove material from a fixed metal component.

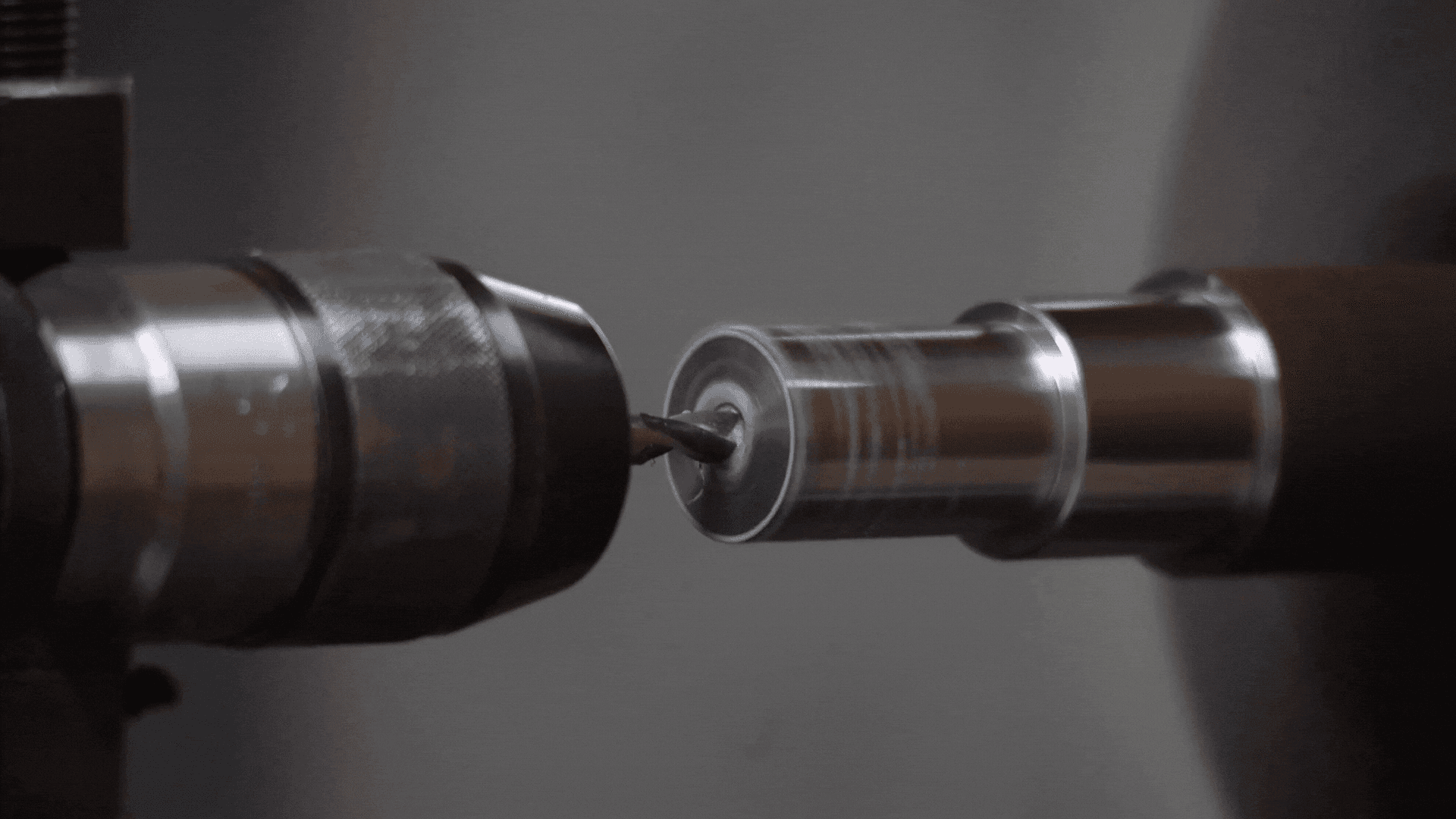

CNC drilling process

CNC Drilling operations produce holes in metal parts with high precision.

When an operator gives the required instructions to the CNC machine, it performs the desired processes to manufacture one or multiple products. CNC machines run on numerical control instead of human ability, but need a machinist to perform and supervise the CNC machining process.

What is subtractive manufacturing?

Subtractive manufacturing is a manufacturing process in which a material, such as metal or plastic, is removed by a cutting tool to create a desired shape or finish.

This process is called "subtractive" because it involves the removal of material from a workpiece to create the final product. In contrast, additive manufacturing involves adding material to create a product.

Subtractive manufacturing processes include machining, turning, drilling, and milling.

Who is a CNC machinist or CNC operator?

A CNC machinist is a skilled worker who operates CNC machines to produce parts and products. CNC machines are machine tools that use computer software to control and automate their movements, allowing them to perform complex operations with high precision and accuracy.

A CNC machinist typically has extensive knowledge of CNC technology and a strong understanding of the manufacturing processes involved. They are responsible for setting up and operating CNC machines, as well as monitoring the quality of the finished product to ensure it meets specifications.

CNC machinists are an essential part of the manufacturing industry, playing a key role in the production of a wide range of parts and products.

How do I find a CNC manufacturer?

Depending on your needs, there are many things you should consider before picking a manufacturing partner. Take a look at the following article describing the most important aspects and features you should look for. Learn how to find the best CNC manufacturers here.

When is CNC ideal?

Many industries take great advantage of CNC manufacturing, mainly because such industries rely on high precision, reliability, and processing materials, among other things. Some of these industries are:

Aerospace

Medical Industry

Electronics

Automotive

Transportation

Energy & heavy industry

Is CNC Manufacturing for me?

CNC can be a wonderful option for production, as it offers great possibilities that can be the perfect match for your needs. However, other manufacturing technologies like 3D printing, Sheet Metal Fabrication, or Injection Molding are alternatives that, in some cases, can be of better use.

Read more about the advantages and disadvantages of CNC manufacturing and decide whether you should be using it today for your parts and products.

Materials for CNC manufacturing

CNC manufacturing can be used to produce parts and products from a wide variety of materials, including metals (such as steel, aluminum, and brass), plastics, and composites.

The specific materials that can be used in CNC manufacturing depend on the type of CNC machine and the manufacturing process being used. For example, CNC milling machines are commonly used to produce parts from metals. In general, most materials that can be machined or molded can be used in CNC manufacturing.

Get Online CNC Machining Orders

Online manufacturing services are convenient and easy to use. With our online manufacturing service, you can easily and quickly order custom parts and products from the comfort of your own home or office, saving you time and hassle.

Wikifactory Marketplace offers you constant guidance and support, allowing you to order exactly the parts and products you need. We continuously work to make manufacturing easier for every designer, engineer, and hardware creative that pushes the world forward with their products.

Submit your RFQ now (Request For Quotation). Do it today and get the price for your parts and products as soon as possible.

Wikifactory is the easiest way to get your product to market.

Get the latest articles on your inbox