Manufacturing

10 innovations that are shaping the industry and driving progress

Jan 16, 2023

Innovation is critical to the success of every industry, and the manufacturing industry is no exception. Innovation drives progress, competitiveness, and efficiency and enables the development of new products and processes to meet consumers’ changing needs and demands. Innovation can also help to address existing challenges.

The manufacturing industry is constantly evolving and adapting to new technologies and innovations. These advancements can transform how products are made and lead to greater efficiency, productivity, and competitiveness. In this article, we will explore the top 10 innovations in manufacturing that are shaping the industry and driving progress. From 3D printing and robotics to advanced materials and the Internet of Things, these technologies have the capacity to revolutionize the way we manufacture products and meet the needs of consumers.

Top 10 Innovations in Manufacturing

3D Printing

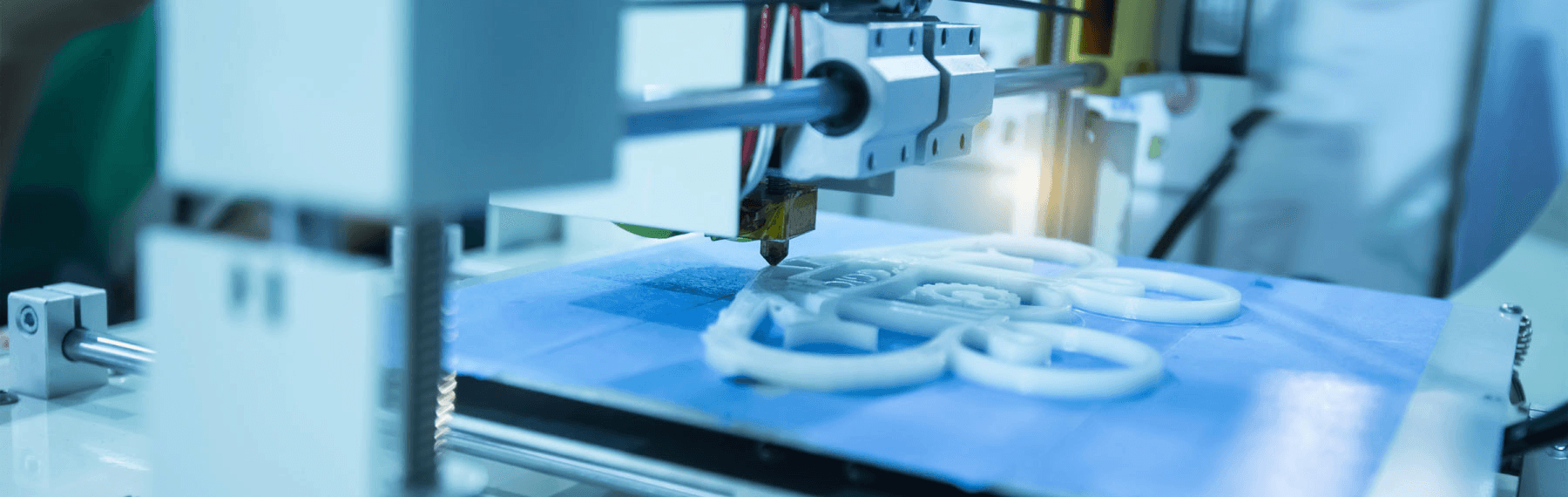

3D printing, also known as additive manufacturing, creates three-dimensional objects by building up layers of material, such as plastic or metal, using computer-aided design (CAD) software. This technology can create complex designs that would be difficult to achieve using traditional manufacturing methods.

3D printing has made it possible to manufacture products quickly, at a lower cost, and with greater precision, opening the door to more customized products. New industries such as 3D-printed prosthetics, aerospace, and automotive parts have grown thanks to this technology’s innovations.

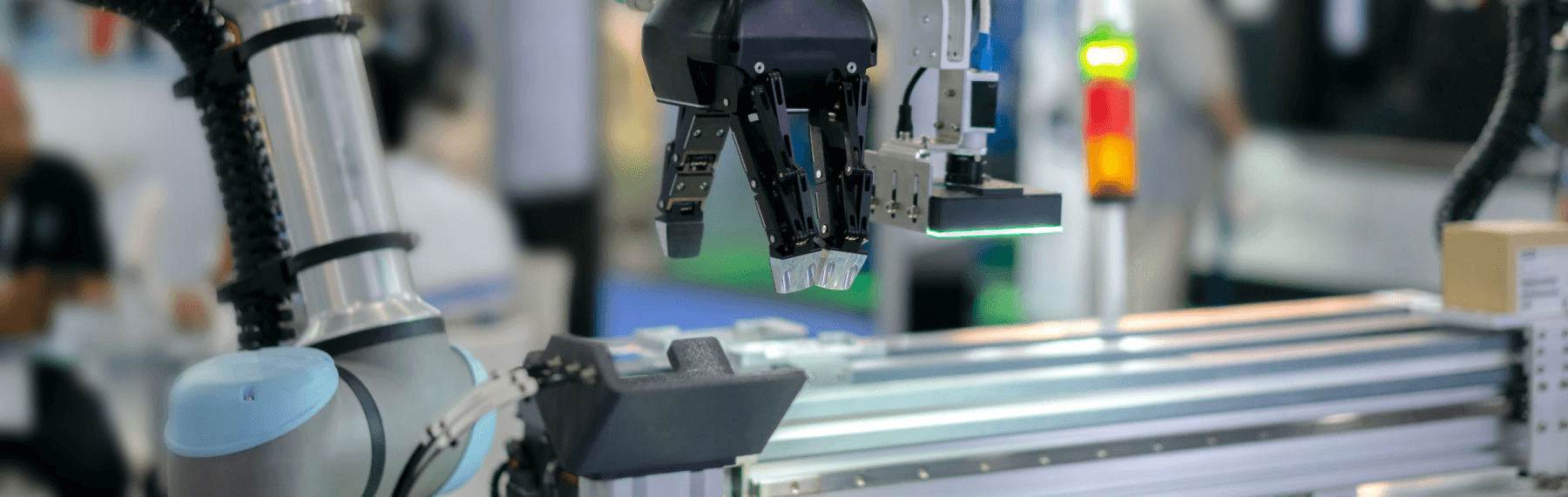

Robotics

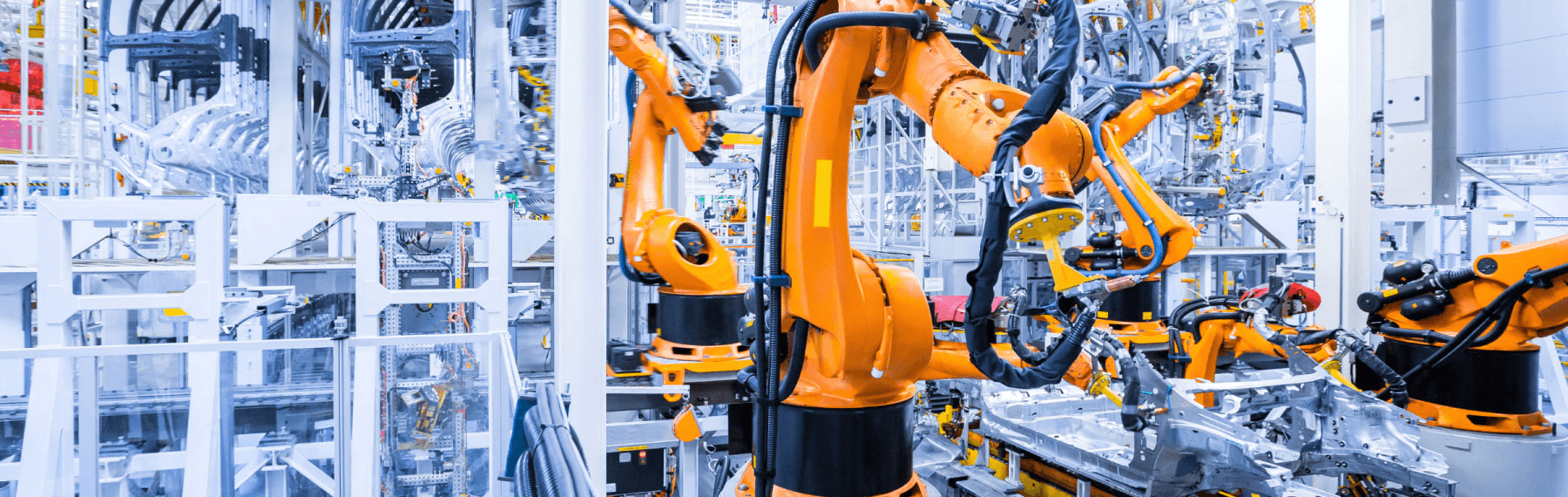

Robotics is a rapidly advancing field that involves the design, construction, operation, and use of robots. These machines perform many tasks, from simple repetitive jobs to complex and sophisticated processes. Robotics technology has come a long way, with today’s robots equipped with advanced sensors, artificial intelligence, and other cutting-edge technologies enabling them to perform tasks with greater precision and efficiency.

The manufacturing industry has seen a significant shift towards automation in recent years, largely thanks to the advancements in robotics technology. Using robotics, manufacturers can increase productivity, reduce costs, and improve their products’ quality faster and with greater precision.

Internet of Things (IoT)

The Internet of Things (IoT) refers to the interconnectedness of devices, machines, and appliances that can communicate and share data. This technology allows for the collection and analysis of data in real-time, making it easier to make informed decisions and improve operations.

Manufacturers optimize and automate their operations by incorporating IoT-enabled devices into their production processes, improving productivity, and reducing downtime. IoT technology has enabled the development of smart factories, where machines and devices communicate to improve production processes, resulting in higher-quality products, lower costs and improved efficiency.

Augmented Reality (AR)

Augmented Reality (AR) overlays digital information on a user’s real-world view, making it possible to interact with virtual objects. Gaming, education, and the entertainment industry are already taking advantage of AR technology in different ways.

By incorporating AR into their production processes, manufacturers can optimize the training and development of new operators, providing them with an immersive way to understand the process, reducing errors, and increasing the learning curve. Product developers, on the other hand, can test and view their designs before sending them to production, saving time and money.

Lean Manufacturing

Lean manufacturing is a business philosophy and technique that maximize customer value while minimizing waste by reducing defects, overproduction, and unnecessary inventory.

Lean manufacturing has created more efficient production processes, resulting in lower costs and increased productivity with the continuous improvement of operations, which leads to the development of new technologies to improve the overall efficiency of the production process. Lean manufacturing encourages using fewer components and eliminating unnecessary features, which leads to the developing of more efficient and cost-effective products.

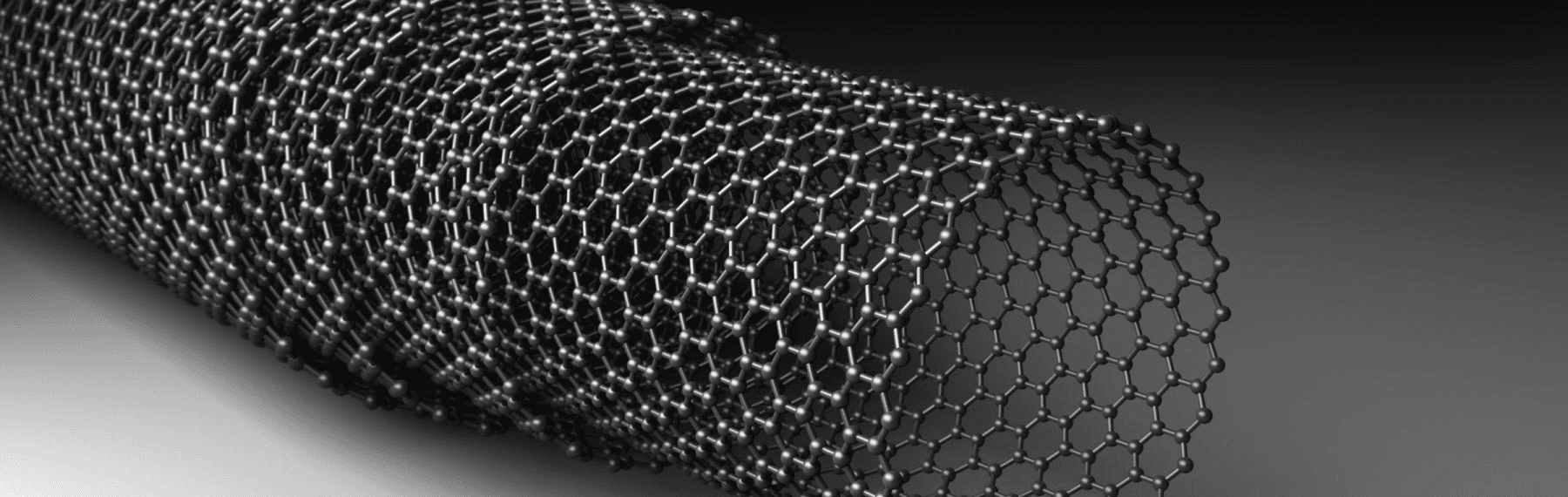

Advanced Materials

Advanced materials possess enhanced properties like high strength, durability, and resistance to extreme temperatures and environments. Product designers and hardware innovators use them in many applications, including aerospace, automotive, and energy production. Some examples of advanced materials include carbon fiber, graphene, and ceramics.

Advanced materials create more efficient and cost-effective products with unique properties that enable them to withstand extreme conditions and environments. For example, using carbon fiber in the aerospace industry has reduced aircraft weight, increased fuel efficiency, and reduced emissions.

Products can be more durable, resistant, and lightweight, which leads to more sustainable products and more efficient designs.

Advanced Process Control

Advanced Process Control (APC) is a technology that allows for real-time monitoring and control of industrial processes. It uses mathematical algorithms and models to optimize the performance of processes, such as temperature, pressure, flow, and chemical composition.

APC enables real-time monitoring and control of industrial processes, leading to performance optimization and reduced process variability. This results in reduced downtime and improved overall equipment effectiveness, which leads to better products in a shorter time frame and at a lower cost.

Predictive Maintenance

Predictive maintenance is a method of monitoring equipment and predicting when maintenance is needed based on data and analysis of the equipment’s condition. It uses sensors, IoT technology, and advanced analytics to track and predict maintenance requirements, scheduling them before equipment failure occurs.

Predictive maintenance incorporations improve equipment effectiveness, helping manufacturers reduce maintenance and repair costs. It also allows for incorporating sensors and IoT technology in the product’s design, making it more efficient and user-friendly.

Collaborative Robots (Cobots)

Collaborative robots, also known as cobots, are designed to work alongside humans in a shared workspace. Cobots have sensors and safety features that enable them to work safely close to humans.

Cobots have a use in a variety of industries. Their capacity to perform repetitive tasks and work in hazardous environments reduces the risk of human error and injuries, increasing efficiency and benefiting the creation of customized products at a faster rate and with greater precision.

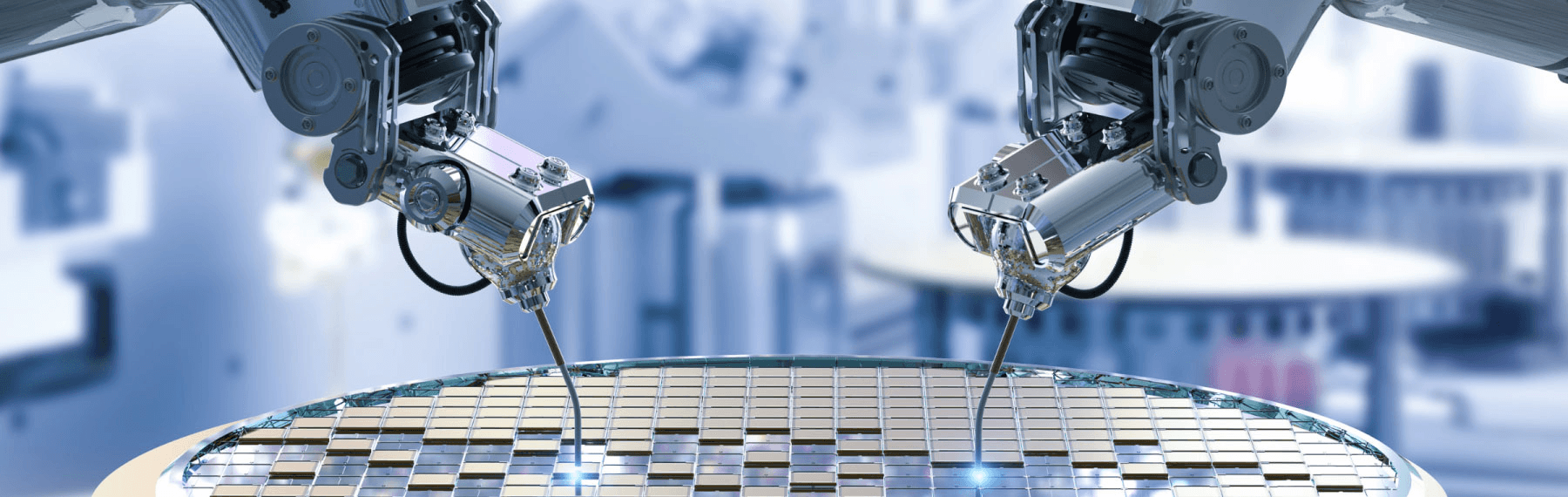

Advanced Manufacturing Technologies

Advanced manufacturing technologies refer to a set of technologies used to improve the efficiency and effectiveness of manufacturing, including nanomanufacturing, biomanufacturing, and digital manufacturing.

These technologies can further change the way products are made and allow for the creation of new materials and products that were not previously possible. New technology and processes are implemented along the production process every year, breaking boundaries in the hardware development industry.

Pushing the Manufacturing Industry Forward

Innovation is a crucial factor in the success and competitiveness of the manufacturing industry. It drives progress and enables the development of new products and processes to meet consumers’ changing needs and demands.

Here are some ways in which innovation is pushing the manufacturing industry forward:

Improving efficiency and productivity: Innovation can help to streamline production processes and reduce waste, leading to lower costs and higher profits.

Enhancing quality: Helping improve product quality and processes, leading to greater customer satisfaction and loyalty.

Increasing competitiveness: Helping manufacturers to differentiate themselves from their competitors and stay ahead of the curve in their market.

Enabling new products and applications: Leading to the development of new materials and technologies, allowing manufacturers to create products that were not previously possible.

Addressing sustainability and environmental concerns: Helping manufacturers reduce their environmental impact and improve resource efficiency, helping to address sustainability and the circular economy.

Innovation is vital in driving progress and competitiveness and will continue to shape the industry’s future. According to a report by the Manufacturing Institute, manufacturers that invest in innovation are more likely to experience growth in sales, employment, and productivity. Companies embracing and leveraging new technologies and innovations will be well-positioned to succeed in an increasingly competitive global market.

What is next in manufacturing?

Are you wondering what the future of manufacturing looks like? Don’t miss out on our in-depth article about the top 10 trends for the manufacturing industry in 2023.

Technologies, such as 3D printing, robotics, advanced materials, and the Internet of Things, are transforming how products are manufactured and making the industry more efficient. By reading our article, stay ahead and get a sneak peek into what’s coming up in the next few years.

Innovative Manufacturing at Hand

In this article, we have talked about how new technologies like 3D printing, robotics, advanced materials, and the Internet of Things are changing the way products are made and making the manufacturing industry more efficient.

While manufacturing is changing and will continue with it, something that shouldn’t change is the production quality. Innovative manufacturing platforms like Marketplace push the boundaries of what traditional manufacturing has to offer.

Experience the power of having a quality-assured network of manufacturers at the reach of your fingers, with just a computer and an internet connection. Innovating is creating the world’s most powerful platform for manufacturing parts and products and making it accessible to every designer, engineer, SME, and hardware professional worldwide.

Get the latest articles on your inbox