Sheet Metal Fabrication

Discover what Laser Cutting can offer you

Dec 19, 2022

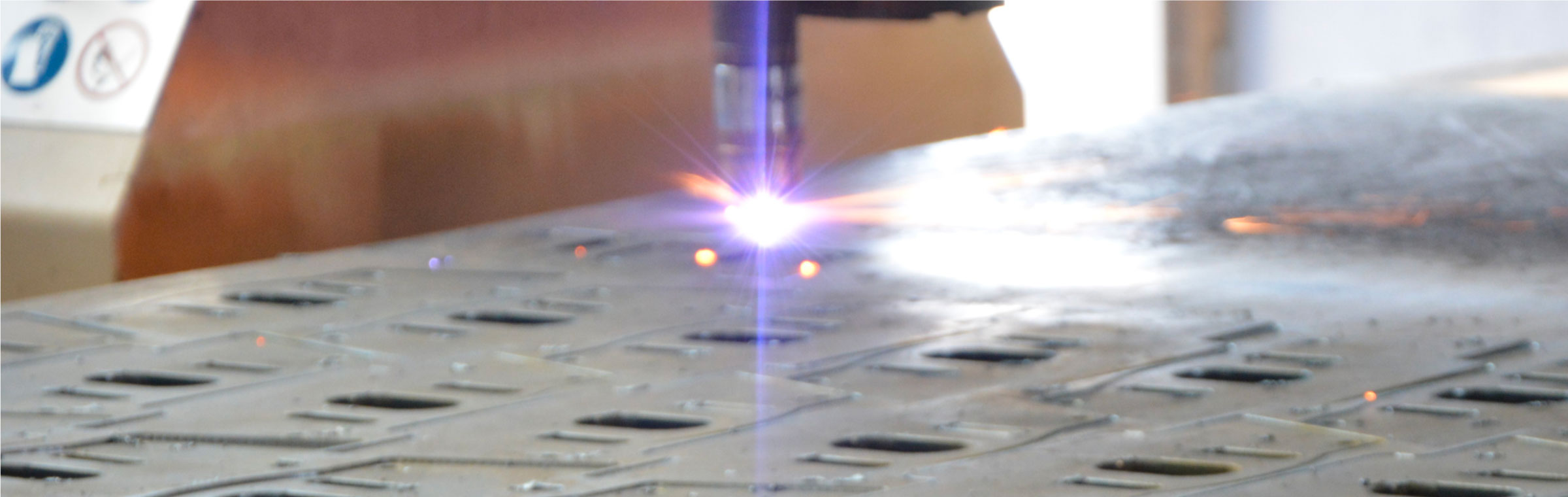

Laser cutting is a Sheet Metal Fabrication method, part of the thermic cutting group, including Plasma Cutting.

This technology is used to cut a wide range of materials where metals make an important part. Laser cutting can cut in manually impossible shapes, opening the door to more complex designs.

How does laser cutting work?

Laser cutting uses a high-density beam directed through optics and moved by CNC (computer numerical control) to cut or engrave a sheet of material. It reproduces a 2D design to cut high-precision jobs. The laser is created by a lasing medium stimulated by an electric discharge inside a closed container, which is then reflected internally until the beam is stimulated enough to exit as a stream of high-energy light capable of performing the desired job.

The laser beam is usually under 0.32 mm in diameter, making for a precise cutting method.

Laser Cutting Material Options

Although laser cutting can cut a wide variety of materials, from wood to rock and foam to fabric, at Wikifactory, we work with metals primarily due to the high reliability of the material, making it ideal for most hardware parts and products designers and engineers produce. Some of the most popular materials are:

Aluminum

Steel

Stainless Steel

Copper

Brass

Industries using Laser Cutting

The aerospace and automotive are two industries taking the most advantage of this technology; however, the versatility of laser cutting manufacturing makes it ideal for all sorts of products in every possible size. It is as simple as requesting a quote and receiving your order anywhere in the world to start producing with this technology.

Benefits and Limitations of Metal Laser Cutting

Some of the most significant benefits of laser cutting are:

High accuracy, allowing for complex shapes with great detail, and capable of working with smaller and more prominent parts and products.

Production speed. Production can start immediately with little preparation when the files are correctly done.

Versatility, due to its capacity to cut and engrave the same piece and work with several materials.

Price, as it is more accessible in comparison with waterjet cutting.

Fewer finishings are needed. Due to its precise cutting and powerful cutting beam, the need for finishings is reduced in most cases.

Some of its limitations are:

Low efficiency on thicker materials, where Plasma or Waterjet cutting may perform better.

High power consumption due to the nature of the process of creating, maintaining, and using the laser.

Plastics can be problematic. Highly specialized professionals must manage some of them since they can produce toxic gases.

Post-processing and finishing after Laser Cutting

Although laser cutting has a cleaner result than plasma cutting, it may still need a post-processing or finishing process to achieve the desired results. Some of the most common procedures include:

Deburring: To remove any resulting sharp or rough edges.

Sanding: To smooth out any rough or uneven surfaces.

Polishing: To create a high-gloss finish on the metal.

Painting: To add color to the metal or to protect it from corrosion.

Anodizing: To create a protective oxide layer on the surface of the metal.

Welding: To fuse two or more metal parts.

Cost-Effective Laser Cutting Online

Laser cutting for sheet metal fabrication can be very cost-efficient when experts manage and produce your order. Request a quote with Wikifactory and access the support from our engineering team and a network of quality-assured manufacturers.

Get the latest articles on your inbox