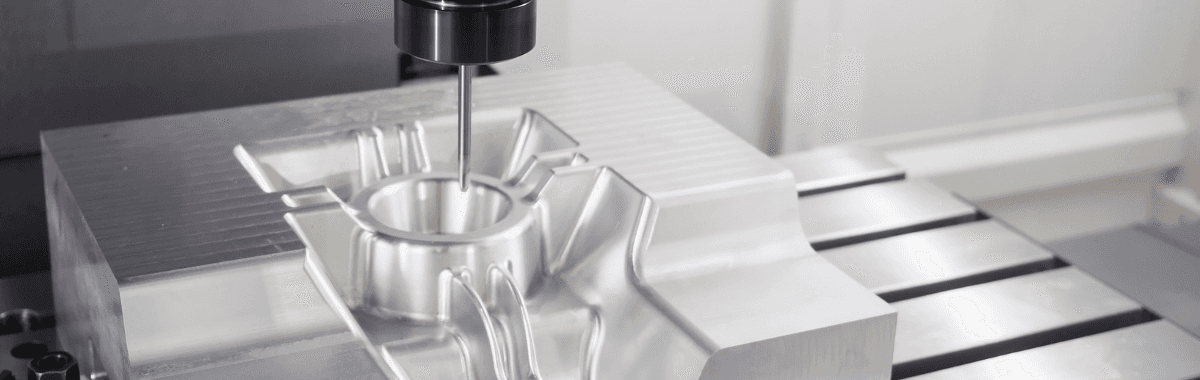

CNC Machining

Seven steps to help you choosing the right material for CNC

Mar 8, 2023

Selecting the right material for your CNC machining project is crucial for ensuring the success of your final product. Choosing an inadequate material may make your product fail to perform as expected or may even break down entirely.

In addition to compromising your product's performance and overall quality, choosing the wrong material can result in increased costs, longer production times, and additional maintenance and repair expenses.

This guide will help you select the perfect material for your CNC-made project. We'll cover the key factors to consider when choosing a material and the properties and advantages of some of the most popular materials used in CNC machining.

Let's dive in and explore how to pick the right material and reduce risks.

Understanding Your Project Requirements

Before selecting a material, it's essential to take your time to fully and clearly understand your product's requirements. Strength, durability, temperature resistance, and cost are some of the key factors you should consider.

Strength

A material's strength is one of the most important factors to consider when picking one. You need to choose a material that can handle the loads or stresses that using your product will put it under. Some key questions to consider include the following:

What is your product's maximum load or weight need to bear?

Will your product be exposed to high levels of impact or shock?

Are there any safety concerns related to the strength of the material?

Durability

Durability is another crucial factor to consider. Go for a material that can withstand the wear and tear of regular use and environmental conditions. Ask yourself some of the following questions:

What is the expected lifespan of your product?

Will your product be exposed to harsh environmental conditions, such as extreme heat or cold?

Will your product be exposed to moisture or chemicals that could cause corrosion or degradation?

Machinability

Machinability is another critical aspect to consider. The easier to machine the material you want, the fewer complications may arise during production and fewer headaches. Try avoiding specialized equipment or expertise. Answer the following:

Can you access the necessary equipment and expertise to machine the material?

Is the material prone to chipping or cracking during machining?

Will the material require specialized tooling or techniques for machining?

Cost

Material costs are just one part of the equation. Every material can have different machining and delivery costs depending on how heavy and resistant it may be.

Choose a material that aligns with your budget.

Do you know the costs of every material you have in mind?

Are there additional costs associated with machining the material, such as specialized tooling or setup fees?

How does the cost of the material compare to alternative materials that meet your project requirements?

Availability

The material's availability is another thing to consider. Make sure you choose a readily available material that you can find easily, especially if you need to order more in the future.

Is your ideal material readily available from suppliers?

Are there any extra lead times or shipping costs associated with obtaining the material?

How does the availability of the material compare to alternative materials that meet your project requirements?

Environmental impact

The environmental impact of every material is becoming an increasingly important factor to consider. Choose a material that aligns with your vision and values by considering the following:

What is the environmental impact of producing or using the material?

Are there any sustainable or environmentally responsible alternatives to the material?

Will the material be disposed of in an environmentally responsible way at the end of its life cycle?

Aesthetics

Finally, your product's final look and feel are also very relevant to you and your audience, especially if the final product will be visible or on display. Go for a material that gives your product both functional and aesthetic benefits.

Make sure to balance to decide on a material that creates a visually appealing final product. Here are a few more questions to guide your decision:

What is your desired appearance or finish of your final product?

Are there any specific color or texture requirements for the material?

How does the appearance of the material compare to alternative materials that meet your project requirements?

Even if you don't have definitive and final answers to all the questions, trying to answer them may guide you in finding the most suitable material to fulfill your product's needs.

Popular Materials for CNC Machining

There are several popular materials for CNC machining, each with its own set of strengths and weaknesses. Here's an overview of some of the most common materials to help you in making a decision:

Aluminum: Aluminum is a lightweight, strong, and easy-to-machine material. It's ideal for applications where weight is a concern, such as the aerospace and automotive industries. Aluminum is also corrosion-resistant, making it a good choice for outdoor applications.

Steel: Steel is a durable and robust material that can take more energy to machine. It is recommended in applications where strength is critical, such as construction and manufacturing. Steel, like aluminum, is corrosion-resistant, making it ideal for weather-exposed applications.

Brass: Brass is a corrosion-resistant and easy-to-machine material. Due to its appearance, it's a common material in applications where its aesthetic properties are important, such as in decorative parts and musical instruments.

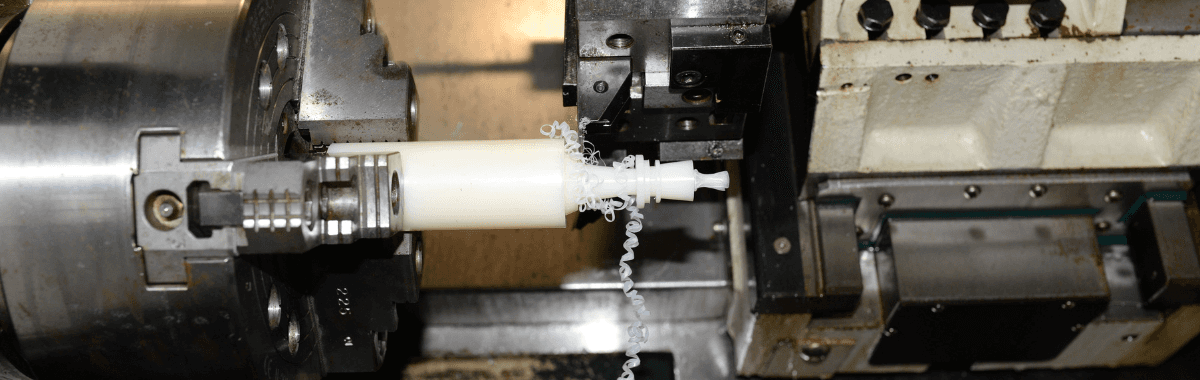

Plastics: Many plastic materials are available for CNC machining, each with unique properties. Some common plastics include polycarbonate, acrylic, and nylon. Plastics are lightweight and easy to machine, making them a good choice for applications where weight matters.

It's also worth noting that in addition to the materials mentioned above, there are also many alloys that can be useful in certain situations.

Alloys are created by combining two or more metals to achieve specific properties that the individual metals cannot provide on their own. For example, aluminum alloys are commonly used in aerospace applications due to their strength and low weight.

Similarly, steel alloys can provide greater strength and durability than standard steel. When considering materials for your CNC machining project, it's important to keep in mind that alloys may offer unique benefits that could be advantageous for your specific application.

Specialty Materials for CNC Machining

Depending on your project requirements, you may need to consider other materials with specific properties to **ensure your product performs as it should**. Here are a few of the most common options available in the market:

Titanium: Titanium is a strong and lightweight material, usually on the expensive side of materials. Beneficial for products where keeping them light is critical, such as aerospace and medical industries. Titanium, like other materials, is highly corrosion-resistant.

Carbon fiber: Carbon fiber is resistant while being one of the lightest materials available with a unique look. It's very popular in several industries, automotive and sporting being two of them.

Ceramics: Ceramics are tough and ideal for heat-resistant tasks but can be brittle. Commonly used in kitchen appliances, ceramics are often underestimated but can be an excellent alternative for many products.

Choosing the Right Material for Your Project

To choose the best material for your project, start by evaluating your requirements and determining the most critical factors. Once you clearly understand your needs, consider the properties of each material and how they align with your requirements.

When evaluating materials, it's essential to consider their sourcing and machining costs. Some materials may be more challenging to machine than others, which can increase the overall cost of your project. In contrast, some materials may require specialized equipment or expertise, which can also impact the cost.

Make as much of an informed decision as possible since only you and your team can reach the best answer based on your research and results to the questions we proposed above.

Start Producing with Engineering Support

Choosing the right material for your CNC machining project is crucial for ensuring your product's success. Take the time to analyze all relevant factors. If the decision comes down to a few materials that can give you equal benefits, try ordering samples to reach a final decision.

By understanding your project requirements and evaluating the properties of different materials, you can make an informed decision that aligns with your needs and budget.

Wikifactory supports companies and entrepreneurs looking to produce top-quality parts and products with worldwide delivery. When you place an order with us, you receive engineering support to solve your doubts and concerns.

If you found this guide helpful, let us know in the comments and share it with your colleagues.

Get the latest articles on your inbox