Supply Chain

Build a risk-free supply chain to remain on top of your competitors

Jan 20, 2023

Supply chain resilience refers to the ability of a business or organization to withstand and recover from disruptions that may occur in the supply chain, from natural disasters to unexpected changes in demand or supply or those caused by geopolitical events and pandemics.

In today’s globalized and interconnected business environment, supply chain resilience is more relevant than ever. According to this report by The Economist, supply chain disruptions can cost global businesses an average of 7-10% of their annual revenue. Additionally, events such as the COVID-19 pandemic have highlighted the importance of resiliency in avoiding the struggle to overcome the related consequences.

At Wikifactory, we offer innovative solutions for addressing supply chain risks and challenges. Keep reading to discover why this matters and how we can improve your business resiliency.

Traditional approaches to supply chain resilience

Traditionally, businesses and organizations have addressed supply chain risks and challenges through a variety of methods, including:

Diversifying their supplier base: By having multiple suppliers for each product or component, businesses can reduce the impact of disruptions caused by a single supplier.

Building buffer stocks: By maintaining a surplus of raw materials or finished goods, businesses can better weather unexpected changes in demand or supply.

Implementing contingency plans: Businesses can develop contingency plans to implement in the event of a disruption, such as temporarily sourcing materials from alternative suppliers or shifting production to other facilities.

Strengthening relationships with key suppliers: Building solid relationships with key suppliers can help businesses better understand and manage their supply chain risks and challenges.

While these approaches are effective in certain situations, they have limitations. Diversifying the supplier base can be costly and time-consuming, and building buffer stocks can tie up capital that could serve other purposes. Contingency plans may only sometimes be feasible or effective in the face of unexpected or unforeseen disruptions. Strengthening relationships with suppliers may be needed to fully mitigate supply chain operations risks and challenges.

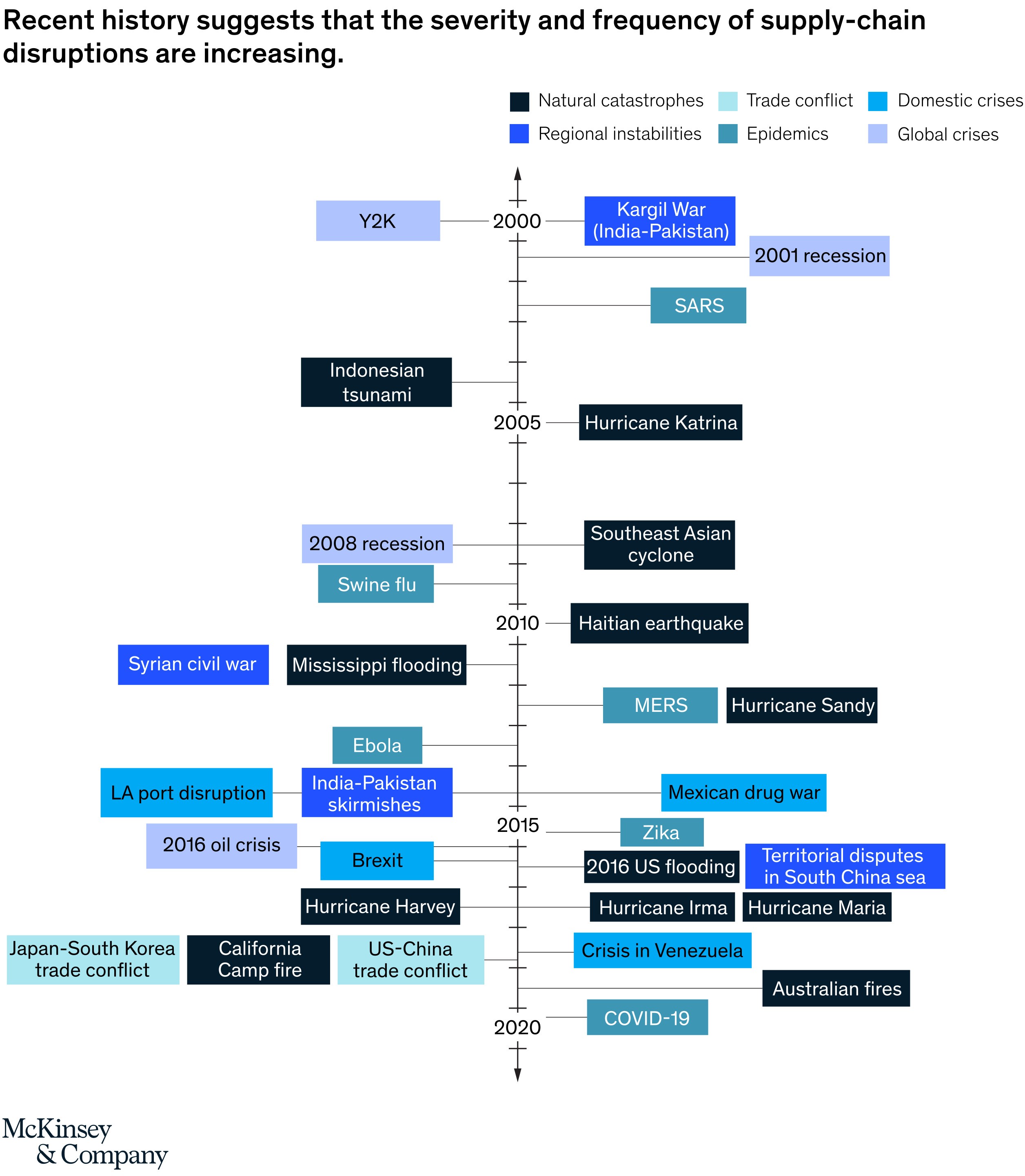

Supply chain disruptions are common

Since 2010, the global supply chain has faced some disrupting situations highlighting the importance of building a resilient supply chain. For example, in 2011, the Tohoku earthquake and tsunami in Japan caused significant trading and manufacturing complications, as many companies relied on Japanese suppliers for critical components and materials. This disaster exposed many businesses’ vulnerabilities in the supply chain and underscored the importance of contingency plans in place to address unexpected disruptions.

The 2017-2018 global shipping crisis was no less disruptive, caused by a combination of factors, including the bankruptcy of Hanjin Shipping and a shortage of containers. This crisis led to significant delays, highlighting the need for businesses to have diversified supplier bases and buffer stocks to weather unexpected events.

In 2015, the port of Rotterdam in the Netherlands, one of the world’s busiest ports, was hit by a major strike that lasted for several weeks. The resulting interruption in the product’s flow through the port had a knock-on effect on the global supply network.

Each one of these events demonstrated the importance of having business contingency plans and alternative sources of supply in place.

The risk is often more expensive than investing

Supply chain shortages and problematic situations can have severe consequences for businesses like yours, ranging from lost sales and market share to increased costs and damage to a company’s reputation affecting customer satisfaction. Understanding the potential impact of these disruptions is crucial for businesses, as it allows them to make informed decisions about how much to invest in strategies to mitigate these risks.

Your company might assess the likelihood and potential impact of different disruptions, such as natural disasters, sudden changes in demand, or geopolitical events. Based on this assessment, you can then determine the appropriate level of investment in strategies such as diversifying its supplier base, building buffer stocks, or implementing contingency plans.

Suppose you understand the magnitude of the losses your business could face from supply chain disruptions and invest in appropriate mitigation strategies. In that case, you can reduce exposure to these risks by taking action.

Why supply chain managers are looking to Wikifactory

An online, on-demand, and agile manufacturing platform like Wikifactory can improve your company’s resilience strategy in several ways. One is our platform’s ability to provide rapid, flexible manufacturing services to your business on demand, which can be especially useful when traditional manufacturing processes are too slow or inflexible to meet changing market demands or supply chain disruptions.

By allowing your company to upload manufacturing designs and specifications online to our platform, we let you receive quotes and place orders for production within hours. We do this to support you in responding quickly to changing market conditions or unexpected disruptions, such as sudden shifts in demand and material shortages.

On top of providing fast turnaround times, we also offer a wide range of manufacturing capabilities, including 3D printing, CNC machining, Sheet Metal Fabrication, and Injection Molding through Marketplace, our highly valued online manufacturing platform. Our diversity capacity makes it easier and more efficient to you sourcing various components and products from one place, reducing the need to manage multiple suppliers and streamlining your supply chain.

Time to take an action

In today’s globalized and interconnected business environment, supply chain complications can have severe consequences, including lost sales, increased costs, and damage to your company’s reputation. Building a resilient supply chain is, therefore, critical for businesses looking to constantly remain on top of their competitors, withstanding and recovering from unexpected events and maintaining their operations and profitability.

At Wikifactory, we’re constantly working to equip companies worldwide with resilient supply chains capable of facing every manufacturing challenge. Try Wikfactory today and give your business the ability to be more agile and responsive in the face of disruptions.

Building a resilient supply chain is more critical than ever for your business. We encourage procurement and supply chain managers to take the relevant actions to ensure their businesses’ success before it’s too late. If you want to discuss your supply chain with us in more detail, contact us here, and we’ll get back to you.

Get the latest articles on your inbox