CNC Machining

Decide if you should use this manufacturing technology

Nov 1, 2022

CNC manufacturing or Computer numerical control (CNC) manufacturing is one of the most effective manufacturing processes available to the public. Even though it is the perfect choice for many parts and products, it might not be the best option in every case. The best way to decide if you should use this manufacturing technology is to explore the advantages and disadvantages of CNC machining.

Through Wikifactory’s Marketplace we help our customers get precision CNC parts and products from our network of quality-assured manufacturers. Our expert intermediators support our buyers in optimizing their online CNC quotes to the precision, price, and predictability they need.

We have used that experience to build the following list of CNC pros and cons to help you make the best decision. If you would like to learn more about what is CNC, what is a CNC machine and more essential aspects of CNC - we’ve prepared another article for you here.

CNC advantages

1. High Precision

Thanks to CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) software in the production process, CNC machines can perform incredibly accurate machining operations on any piece, in contrast, to manually operated machines with a higher chance of errors. Thanks to advanced technology, milling, turning, or drilling are very reliable CNC manufacturing processes with a high degree of replicability.

2. Time Efficient

CNC machines can run almost non-stop for several days, only stopping for maintenance, which means that CNC manufacturing has shorter production times than other technologies.

3. Production Capacity

Whether you need to produce a single piece or jump into mass production, CNC machines can manufacture one or multiple samples from the same design, opening the door to batch-process manufacturing.

4. Range Of Materials

From metal to plastic and beyond, there is a wide selection of materials that can be machined. Combining such materials with different CNC manufacturing processes results in endless production possibilities.

5. Reliability

Because CNC machining processes run on software instead of human force, errors are virtually zero when the file is correct and designed with DFM (design for manufacturing) in mind. CNC's reliable production will deliver what you expect every time.

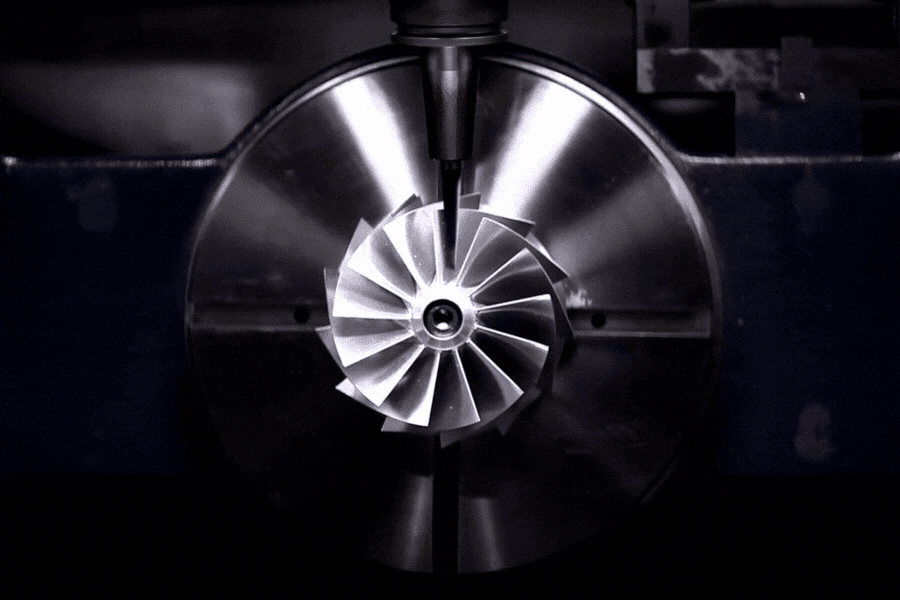

6. Complex geometry

CNC machines come with 2, 3, 4, 5, 6, or 7 processing axes, allowing for high manufacturing complexity capacity. You can produce most products, given that the design is machinable and that the manufacturing center of your choice has the correct machine for your production needs.

If you want to know how to select the best CNC manufacturers for your products, look at this article we created to help you.

7. Scalability

You don’t need to worry about having one, ten, or a thousand pieces produced with the same precision in specifications and quality. CNC machining is ideal for you whether you need one piece or hundreds, and even if you request an additional batch later, you will always get what you ordered.

8. Energy Efficient

We understand that you might also worry about the environmental impact of using CNC as your manufacturing technology. Good news for you: CNC machining is very energy efficient, which means it will use the least amount of energy possible thanks to its highly advanced CAM software that allows for pre-production processing. As a flexible production technology, it is possible to produce on demand and reduce inventory to reduce carbon emissions.

CNC disadvantages

1. Costly

Depending on what you intend to produce, CNC might not be the best option for you in terms of pricing. CNC manufacturing costs depend on production units, size, material, time, complexity, and any other particularity of your order. It is decisive to consider the stage of your product; is it the time to use CNC, or could you produce a prototype with a different manufacturing technology and material?

2. Size Restrictions (both big and small)

Keep in mind there are limits to what a CNC machine can manufacture. CNC machines come in different sizes, which means manufacturing size limitations. To produce larger pieces, you might need to reconsider splitting them into smaller parts (which will also be very helpful in the shipping process), consider welding to join parts if needed, or look for alternative manufacturing technology.

On the other hand, if the piece you intend to produce is very tiny, CNC might again not be your best option. If the material you choose is fragile, it will probably break during production, or it won’t be able to be processed from the beginning. In case of doubts, our team of experts can suggest the best manufacturing technology depending on your needs.

3. Material Waste

This one greatly depends on your design qualities. CNC is a subtractive manufacturing process that can generate unnecessary waste if you need to remove too much material to achieve your design. If your project has a very intricate design, maybe CNC is not the best fit in this scenario.

4. Design Limitations

It is fundamental to understand what CNC machines can manufacture by machining, milling, or drilling. Specific features such as sharp inner angles, cavities, and extra-thin walls or diminutive holes can be challenging or even impossible to achieve with CNC machines. Your option could be making your design CNC-friendly or using an alternative manufacturing technology for your finished products.

5. Operation Errors

Although highly reliable, CNC fabrication can still have errors in their production lines, mainly due to poor training or little experience from the operations team. Cut out as many risks as possible and choose manufacturers that have proven or can prove the capacity to produce high-quality pieces.

Wikifactory only works with top manufacturers with proven experience in manufacturing and problem-solving, offering you an error-proof CNC fabrication workflow that you can access here.

6. Material Availability

Is the material that you need hard to find or process? As with any manufacturing process, there are certain limitations when it comes to materials. Not every machine can process every material. Double-check that the material you need fits your project’s needs and the manufacturer’s capacity to avoid undesired surprises.

Check out this guide on How to pick the right material for your project in 5 steps, a light read that can save you time and money in the future if you’re getting started.

7. Time for Mass Production

If you’re looking to produce one design in great numbers, CNC is a great choice. Still, we would encourage double-checking other manufacturing technologies, such as Sheet Metal Fabrication or even Injection Molding, which excels particularly when it comes to producing thousands of pieces.

8. Lack of reliable centers

Lastly, we can’t avoid mentioning the importance of working with a CNC manufacturer that can cover all your needs while excelling in supporting you along the process. Particularly relevant when the design has a higher level of complexity and you still have questions about the best material, a DFM team can make the difference between possible and impossible.

Do some research to find the best fit for you, or check out this helpful article explaining the most important aspects of working with a CNC manufacturer.

CNC checklist for production

Take a look at this checklist for CNC manufacturing, a guiding list of key aspects in considering CNC as your manufacturing option. It will support you in making the best decision taking into consideration your previous knowledge, your product qualities, design for manufacturing features, and your needs and expectations.

Best CNC prototyping platform

Now that you have a better understanding of the pros and cons of CNC machining, you can start prototyping. Marketplace is Wikifactory’s manufacturing platform designed for agile and effective prototyping and manufacturing with different types of manufacturing processes.

Request your quote here and get access to quality-assured manufacturers, engineering support, and worldwide delivery.

Do you have a complex manufacturing request? Book a call here. We will be happy to support you.

Get the latest articles on your inbox