Product Development

Learn how to make efficient prototypes

Mar 24, 2023

Have you ever had a product idea but didn't know how to bring it to life? You may have spent countless hours planning and designing, but taking the next step of creating a prototype can leave you feeling a little lost.

You may find yourself wondering: What materials do I need? What manufacturing technology should I use? How do I ensure a successful prototyping process?

Creating a successful prototype requires careful planning, attention to detail, and an understanding of the potential pitfalls of the process. In this guide, we will explore the most critical steps and considerations to help you create a successful prototype.

How to make a Prototype

Here is a list of steps to help you create a prototype. It will also help you manage the process in a comfortable and controlled way:

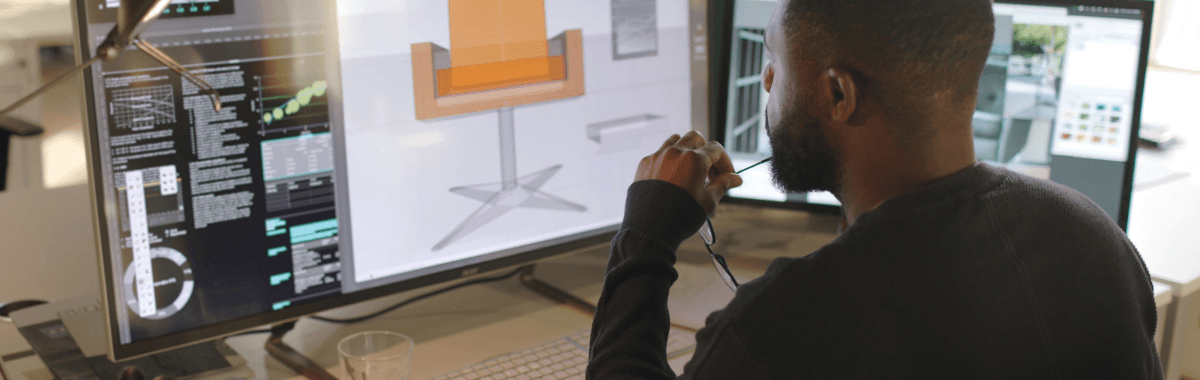

01 Getting Your Design Ready

Before jumping into the prototyping process, it's essential to ensure that your design is ready. We recommend you double-check your target users' needs and preferences, clearly understand your product's functionality and necessary features, and create detailed sketches or 3D models to help you make decisions.

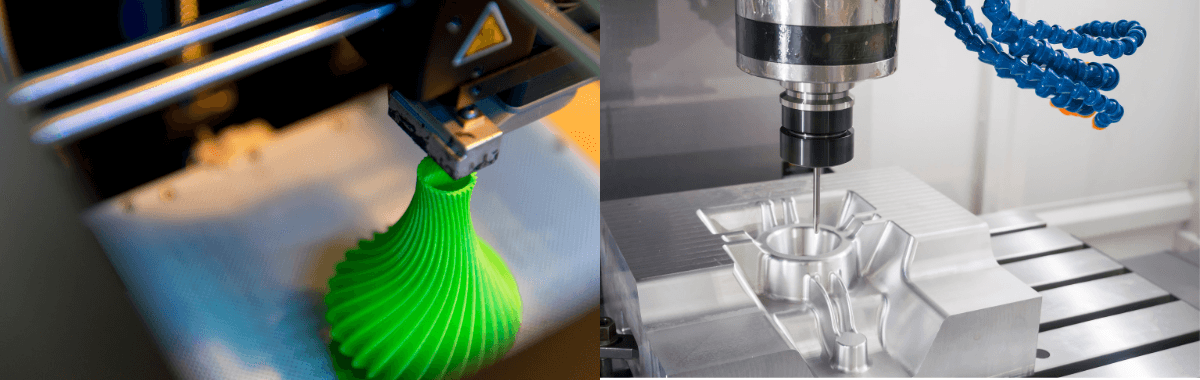

02 Selecting the Manufacturing Technology

Another thing you need to consider during the early stages of your process is which manufacturing technology you need to make your prototype. Some common options include 3D printing and CNC machining, but the appropriateness of each one will depend on your product's needs and prototyping goals.

Each technology has its advantages and disadvantages, so it's essential to understand the capabilities and limitations of each option before making a decision.

03 Preparing Your Files

Once you have decided which manufacturing technology you will be using, preparing your files according to the manufacturer's guidelines is essential.

You may need to adjust your model's dimensions, export your files in the appropriate formats, and ensure that your files are error-free and ready for production.

In any case, don't worry too much about getting it perfect on the first go. When you manufacture with Wikifactory, you will receive support along the process, so if something is wrong with your files, our team will let you know ASAP so your prototyping workflow moves on quickly.

04 Specifying Materials and Finishes

Choosing the appropriate materials and finishes for your prototype can significantly impact its overall quality and performance. Consider your prototype's purpose and choose a material based on how strong, durable, or cost-efficient you need it to be.

Wikifactory's support team will work closely with you to help you identify the most appropriate options for your project in case you're not sure.

05 Providing Detailed Instructions

When submitting your files for production, provide detailed instructions. Include information on specific features, tolerances, and other critical details essential to your prototype's success.

06 Ordering Your First Prototype

Once you feel your proof of concept is ready and have decided about materials, technologies, finishings, and everything else, it's time to order your first prototype.

The best way to do it is to upload your file here in the accepted formats and request your prototype's quote with all the specifications you need. You will receive your quote specifying the cost and lead times. Remember to include your address for shipment costs (don't worry, we have worldwide shipping services).

07 Reviewing and Getting feedback

Once you receive your prototype, it's essential to review it carefully and solicit feedback from others, such as potential users or stakeholders.

Use the feedback to identify areas for improvement and refine your design, which is crucial for any product's development process.

08 Iterating and Ordering a New Prototype

Based on your feedback, you may need to iterate your design and order a new prototype to continue refining your product. It's essential to be patient and willing to make changes based on feedback to ensure the success of your prototype.

09 Getting Assistance if You Need It

If you're new to the prototyping process or encounter challenges along the way, it's helpful to seek assistance from experts or mentors. This can help you navigate the process and overcome obstacles more effectively.

You can always contact our support team by clicking the blue bubble in the floating bottom right corner of your screen. If we can assist you, rest assured we will.

10. Involving Others if You Lack Technical Capacity

Last but not least, if you need more technical expertise in certain areas, such as design or engineering, consider involving others in the prototyping process.

Open the door to collaborating with professionals or seeking online resources and tutorials to help you overcome technical challenges.

Additional Prototyping Considerations

While the above steps are critical to creating a successful prototype, there are a few additional considerations to keep in mind:

Cost considerations

The cost of producing your prototype may vary depending on the type of manufacturing technology, materials, finishes, and design complexity.

Before sending your files for production, it's important to consider your budget. Prototyping requires you to invest some money, but do it smartly.

Shipping and delivery

Make sure to consider shipping and delivery times in your plan. These services can add an extra cost if you need express delivery.

Plan accordingly and save some money by leaving some margins so you can save money on the delivery. However, when time is fundamental, it may be worth spending a little extra to accelerate your process.

Legal considerations

Depending on the nature of your product, there may be legal considerations to consider before sending your prototype to production. For example, if your product includes copyrighted material or technology, you must ensure that you have permission to use it.

If your product is subject to safety or environmental regulations, you need to ensure that your prototype meets these requirements.

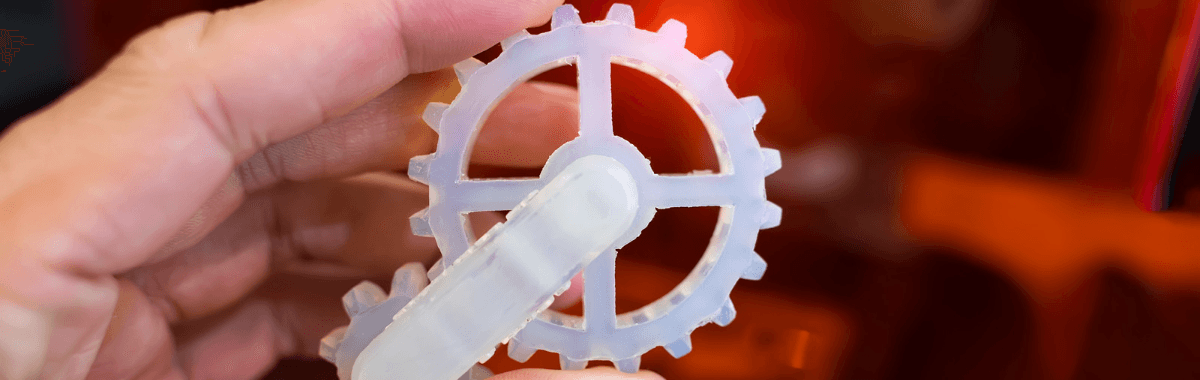

A prototyping service that covers your needs

Prototyping is a fundamental part of the product development process. It allows you to test and refine your design and identify potential issues before batch producing. Follow the steps in this guide, and you will maximize your chances of getting a great product with a smooth process.

To recap:

Finish your design;

Select your preferred manufacturing technology;

Prepare your file for production;

Choose your desired materials and finishes;

Include detailed instructions in your order;

Order your prototype;

Review it and iterate; and

Seek assistance or involve others when your process needs it.

Upload your files here and start rapid prototyping today with a quality-assured manufacturer, top engineering support, and worldwide delivery. Get your product development process moving faster than ever.

Did you find this article helpful? Feel free to share it with your network so they can benefit too from it. Give it a like or leave a comment to help others know about it.

Get the latest articles on your inbox